Burrs matsala ce da ta zama ruwan dare wajen sarrafa karafa, kamar hakowa, juyawa, niƙa, da yanke ƙarfe...

Ɗaya daga cikin haɗarin burrs shine cewa suna da sauƙin yanke!Don cire burrs, ana buƙatar aiki na biyu da ake kira deburring yawanci.3 deburring da ƙarshen ƙarshen madaidaicin sassa na iya yin lissafin kashi 30% na farashin ɓangaren da aka gama.Hakanan, ayyukan gamawa na biyu suna da wahalar sarrafa kansa, don haka burrs da gaske sun zama matsala mai wahala.

Yadda za a warwareBURRS

1 Deburing da hannu

Wannan hanya ce ta al'ada da aka saba amfani da ita, ta amfani da fayiloli (fayil ɗin hannu da fayilolin pneumatic), takarda yashi, sandar bel, kawuna, da sauransu azaman kayan aikin taimako.

DisadvanTages: Kudin aiki yana da tsada, inganci ba shi da yawa, kuma yana da wahala a cire hadaddun ramukan giciye.

Abubuwan da ake amfani da su: Abubuwan buƙatun fasaha don ma'aikata ba su da girma sosai, kuma ya dace da simintin gyare-gyare na aluminum gami da ƙananan burrs da tsarin samfur mai sauƙi.

2 Mutuwar yanke hukunci

Ana aiwatar da ɓarna ta hanyar amfani da mutuƙar samarwa da naushi.

Hasara: Yana buƙatar takamaiman adadin mutu (m mutu, fine die) farashin samarwa, kuma yana iya buƙatar yin siffa ta mutu.

Abubuwan da ake amfani da su: Ya dace da simintin gyare-gyaren alloy na aluminum tare da sassauƙan rabuwar sassa, kuma inganci da lalata tasirin sun fi na aikin hannu.

3 Niƙa da ɓata lokaci

Wannan nau'in cirewa ya haɗa da rawar jiki, fashewar yashi, rollers, da sauransu, kuma a halin yanzu ana amfani da tsire-tsire masu yin simintin.

Hasara: Akwai matsala cewa cirewar ba ta da tsabta sosai, kuma ana iya buƙatar sarrafa kayan aikin hannu na saura burrs ko wasu hanyoyin deburring.

Abubuwan da suka dace: dace da ƙananan simintin ƙarfe na aluminum gami da manyan batches.

4 Daskararre bazuwar

Yi amfani da sanyaya don ƙwanƙwasa bursu da sauri, sannan a fesa majigi don cire burar.Farashin kayan aikin kusan 200,000 ko 300,000;

Abubuwan da ake amfani da su: Ya dace da simintin gyare-gyare na aluminum gami da ƙananan kauri na bango da ƙaramin ƙara.

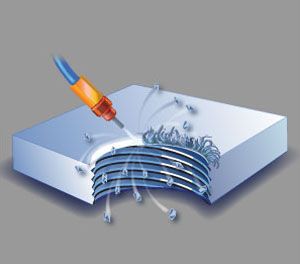

5 Ƙaunar fashewa mai zafi

Har ila yau ana kiran maɓalli na thermal, fashewar fashewa.Ta hanyar shigar da wasu iskar gas mai ƙonewa a cikin tanderun kayan aiki, sannan ta hanyar aikin wasu kafofin watsa labarai da yanayi, iskar gas ɗin yana fashewa nan take, kuma ana amfani da makamashin da fashewar ke haifarwa don narke da cire burar.

Rashin hasara: kayan aiki masu tsada (miliyoyin daloli), manyan buƙatun fasaha don aiki, ƙarancin inganci, sakamako masu illa (tsatsa, lalata);

Abubuwan da ake iya amfani da su: Ana amfani da su a cikin wasu filaye masu madaidaici, kamar su daidaitattun sassan mota da sararin samaniya.

6 Deburing na injin sassaƙa

Farashin kayan aiki ba su da tsada sosai (dubun dubbai).

Abubuwan da ake amfani da su: Ya dace da tsarin sararin samaniya mai sauƙi da sauƙi da matsayi na ɓata lokaci.

7 Keɓancewar sinadarai

Yin amfani da ƙa'idar amsawar electrochemical, sassan da aka yi da kayan ƙarfe na iya zama ta atomatik kuma zaɓaɓɓu.

Abubuwan da ake amfani da su: dace da burrs na ciki waɗanda ke da wuya a cire su, dace da ƙananan burrs (kauri ƙasa da wayoyi 7) na samfurori irin su famfo da jikin bawul.

8 Electrolytic deburring

Hanyar injin lantarki don cire aluminum gami da mutu-simintin burrs ta hanyar lantarki.Electrolytic deburring ya dace don cire burrs a cikin ɓoyayyun sassan aluminum alloy die simintin gyare-gyare, ramukan giciye ko sassa tare da siffofi masu rikitarwa.Ingancin samarwa yana da girma, kuma lokacin cirewa gabaɗaya ƴan daƙiƙa ne kawai zuwa dubun daƙiƙai.

Lalacewar: Electrolyte yana da lalacewa zuwa wani ɗan lokaci, kuma kusancin burar sassan kuma ana sanya shi da electrolysis, saman zai rasa haskensa na asali, har ma yana shafar daidaiton girman.Ya kamata a tsaftace simintin simintin gyare-gyare na aluminum da kuma tabbatar da tsatsa bayan an lalatar da shi.

Abubuwan da ake amfani da su: Ya dace da ƙaddamar da kayan aiki, sanduna masu haɗawa, jikin bawul da ramukan ramukan mai, da zagaye na sasanninta masu kaifi.

9 Babban matsi na ruwa jet deburring

Yin amfani da ruwa a matsayin matsakaici, zai iya amfani da ƙarfin tasirinsa nan take don cire burs da walƙiya da aka haifar bayan sarrafawa, kuma a lokaci guda, yana iya cimma manufar tsaftacewa.

Fursunoni: Kayan aiki masu tsada

Abubuwan da ake amfani da su: galibi ana amfani da su a cikin zuciyar motoci da tsarin sarrafa injina na injinan gini.

10 Ultrasonic deburring

Niƙa na al'ada na al'ada yana da wahala a magance bursu kamar ramuka.Tsarin mashin ɗin da aka yi amfani da shi na yau da kullun (gudanar ruwa ta hanya biyu) yana tura abrasive ta hanyar silinda guda biyu a tsaye gaba dayan abrasive don sanya shi gudana baya da gaba a cikin tashar da aka kirkira ta hanyar aikin aiki da daidaitawa.Shigarwa da kwararar ɓarna a cikin kuma ta kowane yanki da aka ƙuntata zai haifar da sakamako mai lalacewa.Ana sarrafa matsa lamba na extrusion a 7-200bar (100-3000 psi), dace da bugun jini daban-daban da lokutan sake zagayowar.

Abubuwan da ake amfani da su: Yana iya ɗaukar 0.35mm microporous burrs, babu burrs na biyu da aka haifar, kuma halayen ruwa na iya ɗaukar hadadden burrs.

11 Tsabtace kwararar ruwa

Niƙa na al'ada na al'ada yana da wahala a magance bursu kamar ramuka.Tsarin mashin ɗin da aka yi amfani da shi na yau da kullun (gudanar ruwa ta hanya biyu) yana tura abrasive ta hanyar silinda guda biyu a tsaye gaba dayan abrasive don sanya shi gudana baya da gaba a cikin tashar da aka kirkira ta hanyar aikin aiki da daidaitawa.Shigarwa da kwararar ɓarna a cikin kuma ta kowane yanki da aka ƙuntata zai haifar da sakamako mai lalacewa.Ana sarrafa matsa lamba na extrusion a 7-200bar (100-3000 psi), dace da bugun jini daban-daban da lokutan sake zagayowar.

Abubuwan da ake amfani da su: Yana iya ɗaukar 0.35mm microporous burrs, babu burrs na biyu da aka haifar, kuma halayen ruwa na iya ɗaukar hadadden burrs.

12 Magnetic deburring

Magnetic nika shi ne cewa a karkashin aikin da wani karfi Magnetic filin, da Magnetic abrasives cika a cikin Magnetic filin suna shirya tare da shugabanci na Magnetic filin, adsorbed a kan Magnetic sanduna don samar da "abrasive goge", da kuma haifar da wani matsa lamba a kan. surface na workpiece, da Magnetic sanduna suna tuki da "abrasives".Yayin da goga ke juyawa, yana riƙe da wani rata kuma yana motsawa tare da saman kayan aikin, don gane ƙarshen farfajiyar aikin.

Features: low cost, fadi da aiki kewayon, dace aiki

Process abubuwa: grindstone, Magnetic filin ƙarfi, workpiece gudun, da dai sauransu

13 Robot nika naúrar

Ƙa'idar tana kama da ɓarna da hannu, sai dai an juya wutar zuwa mutum-mutumi.Tare da goyan bayan fasahar shirye-shirye da fasahar sarrafa ƙarfi, ana samun sassauƙan niƙa (canjin matsa lamba da sauri), kuma fa'idodin ɓarna na robot sun shahara.

Idan aka kwatanta da mutane, mutum-mutumi suna da halaye: ingantaccen aiki, ingantaccen inganci, da tsada mai tsada

Burrs a cikin Ƙalubalen Niƙa na Musamman

A cikin sassan niƙa, ƙaddamarwa ya fi rikitarwa kuma ya fi tsada, saboda ana samun burrs da yawa a wurare daban-daban masu girma dabam.Wannan shine inda zabar madaidaitan sigogin tsari don rage girman burr ya zama mafi mahimmanci.

Lokacin aikawa: Satumba-29-2022