A cikin tsarin yankewa, saboda ƙarfin yankewa, bangon bakin ciki yana da sauƙi don lalacewa, yana haifar da wani abu na ellipse ko "kwagu" tare da ƙananan tsakiya da manyan iyakar.Bugu da ƙari, saboda ƙarancin zafi mai zafi a lokacin sarrafa bawoyi na bakin ciki, yana da sauƙi don samar da nakasar thermal, wanda ke da wuya a tabbatar da ingancin sassa.Bangarorin da ke gaba ba kawai suna da wahalar matsawa ba, har ma da wahalar sarrafawa.Sabili da haka, dole ne a tsara hannun riga na bakin ciki na musamman da shingen kariya.

Process bincike

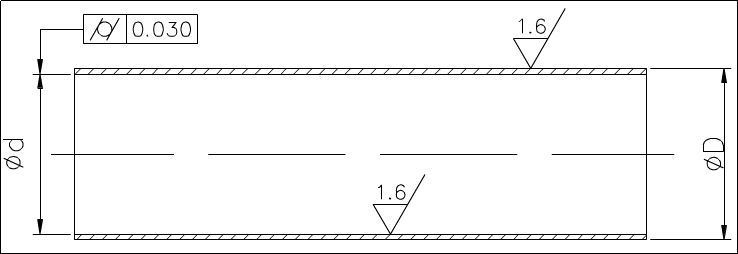

Dangane da buƙatun fasaha da aka bayar a cikin zane, ana sarrafa kayan aikin ta hanyar bututun ƙarfe mara nauyi, kuma ƙarancin saman rami na ciki da bangon waje shine Ra1.6 μ m.Ana iya gane shi ta hanyar juyawa, amma cylindricity na rami na ciki shine 0.03mm, wanda ke buƙatar manyan buƙatu don sassa na bakin ciki.A cikin samar da taro, hanyar tsari tana da wahala kamar haka: blanking - magani mai zafi - juyawa ƙarshen fuska - juya excircle - juyawa rami na ciki - dubawa mai inganci.

Tsarin "Machining na ciki" shine mabuɗin sarrafa inganci.Yana da wahala a tabbatar da silinda 0.03mm lokacin yankan rami na ciki na harsashi ba tare da bangon siliki na siliki ba.

Mabuɗin fasaha don juya ramuka

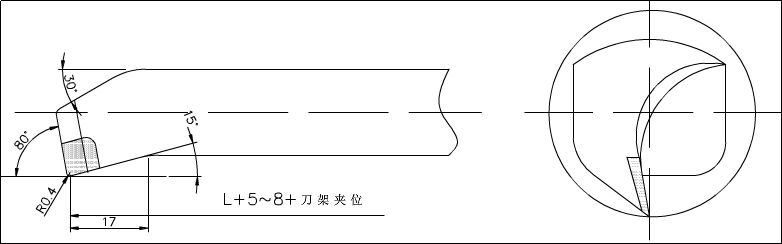

Mabuɗin fasaha na juya ramuka shine don magance matsalolin rigidity da guntu cire kayan aikin jujjuya ramin ciki.Don inganta ƙaƙƙarfan kayan aikin jujjuya ramin ciki, yakamata a ɗauki matakan da suka biyo baya:

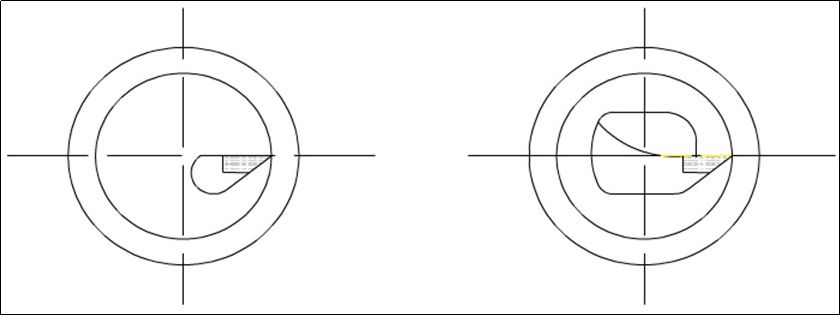

1) Ƙara yankin giciye na kayan aiki kamar yadda zai yiwu.Gabaɗaya, tip na kayan aikin jujjuya rami na ciki yana sama da kayan aikin kayan aiki, don haka yanki na ɓangaren kayan aikin yana ƙasa da 1/4 na yanki na ramin, kamar yadda aka nuna a cikin adadi mai zuwa.Idan tip na kayan aikin juyawa na ciki yana samuwa a kan tsakiyar layi na kayan aiki na kayan aiki, yanki na yanki na kayan aiki a cikin rami zai iya karuwa sosai, kamar yadda aka nuna a cikin adadi mai zuwa.

2) Tsawon tsayin kayan aiki na kayan aiki zai zama 5-8mm ya fi tsayi fiye da tsawon aikin aikin kamar yadda zai yiwu don ƙara ƙarfin ƙarfin kayan aiki da kuma rage girgiza yayin yankewa.

Magance matsalar cire guntu

Ya fi sarrafa yankan kwarara shugabanci.M kayan aikin juyawa suna buƙatar cewa guntu yana gudana zuwa saman don a yi masa injin (guntu na gaba).Don haka, yi amfani da kayan aikin jujjuya ramin ciki tare da ingantacciyar ƙima, kamar yadda aka nuna a cikin adadi mai zuwa.

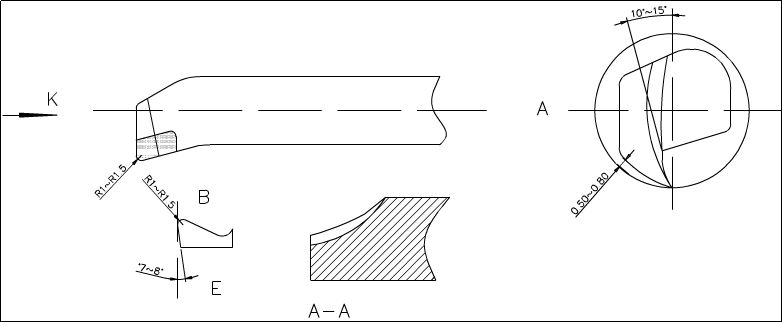

A cikin aiwatar da juyi mai kyau, ana buƙatar jagorar kwararar guntu don karkatar da guntu na gaba zuwa tsakiya (cire guntu a tsakiyar rami).Sabili da haka, ya kamata a biya hankali ga jagorancin niƙa na yankan lokacin da za a yi amfani da kayan aiki.Hanyar cire guntu yakamata ta bi madaidaicin baka gaba.Kamar yadda aka nuna a cikin hoton da ke ƙasa, kayan aiki mai kyau na M-type na yanzu yana da ƙarfin juriya mai kyau, juriya, ƙarfin tasiri, mannewa da karfe, da juriya na zafin jiki.

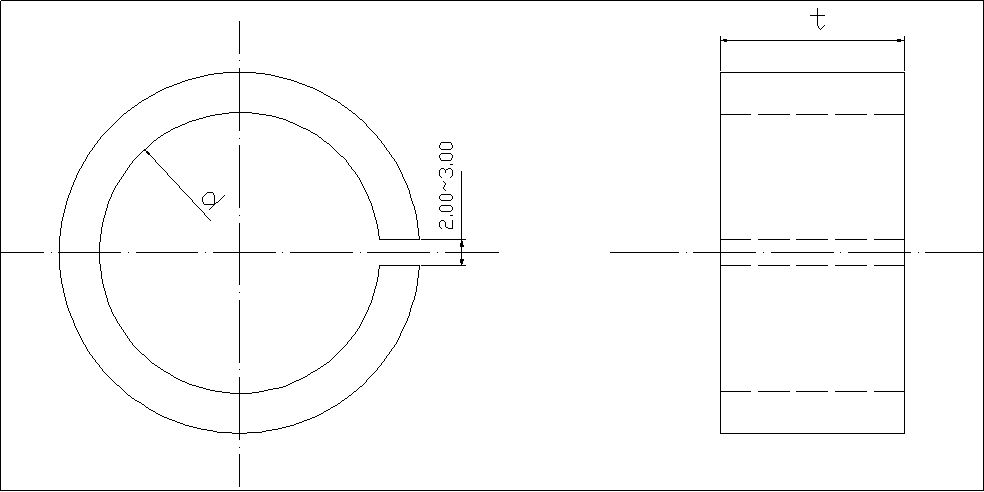

A lokacin niƙa, bisa ga baka na aiki (tare da baka na layin ƙasa na kayan aiki), kusurwar gaba tana zagaye zuwa kusurwar arc na 10-15 °, kuma kusurwar baya tana 0.5-0.8mm daga bango.Matsakaicin kusurwa na c shine § 0.5-1 a cikin k shugabanci da R1-1.5 a batu B tare da guntu guntu.Matsayin baya na sakandare ya dace da niƙa zuwa 7-8 °.Nika maki AA a gefen ciki na E cikin da'irar don fitar da tarkacen waje.

Phanyar rocing

1) Dole ne a yi garkuwar shaft kafin yin injin.Babban aikin kariyar shaft shine rufe rami mai jujjuya hannun rigar bakin ciki tare da girman asalin kuma gyara shi tare da cibiyoyi na gaba da na baya, ta yadda zai iya sarrafa da'irar waje ba tare da nakasawa ba, da kuma kula da ingancin sarrafawa. da daidaito na waje da'irar.Sabili da haka, sarrafa sandar kariyar itace maɓalli na sarrafa simintin katanga.

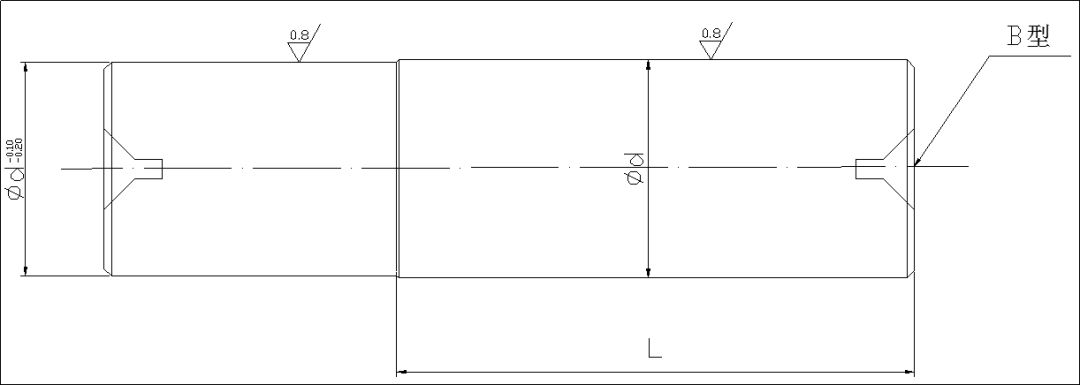

45 #carbon tsarin zagaye karfe don sarrafa m amfrayo na retaining shaft;Juya fuskar ƙarshen, buɗe ramukan tsakiya masu siffar B a ƙarshen duka biyun, ku sanya da'irar waje ta zama m, kuma ku bar izinin 1mm.Bayan maganin zafi, quenching da tempering, sake fasalin, da kuma juyi mai kyau, za a tanadi izinin 0.2mm don niƙa.Wurin da aka murƙushe wutar za a sake fuskantar magani mai zafi tare da taurin HRC50, sannan a niƙa shi da injin niƙa, kamar yadda aka nuna a cikin adadi mai zuwa.Daidaiton ya zama mai gamsarwa kuma za a iya samuwa a shirye bayan kammalawa.

2) Domin kammala aiki na workpiece a lokaci guda, da m amfrayo ya kamata da clamping matsayi da yankan izni.

3) Da farko, bayan maganin zafi, zafin jiki, da gyare-gyare, taurin ulun amfrayo shine HRC28-30 (a cikin kewayon machining).

4) Kayan aikin juyawa shine C620.Da farko, sanya tsakiyar gaba a cikin mazugi na sandar don gyarawa.Don hana nakasawa na kayan aiki yayin danne hannun riga mai katanga, ana ƙara buɗaɗɗen madauki mai kauri, kamar yadda aka nuna a cikin adadi mai zuwa.

Don kula da samar da yawan jama'a, ana sarrafa ƙarshen zobe na waje na harsashi na bakin ciki zuwa nau'in nau'in d, mai mulki yana danne axially, kuma harsashi na bakin ciki yana matsawa lokacin jujjuya ramin ciki don inganta inganci. kuma kula da girman.Idan akai la'akari da yankan zafi, yana da wuya a iya sarrafa girman girman aikin aikin.Za a yi allurar isasshen ruwan yanka don rage nakasar zafi na kayan aikin.

5) Matsar da workpiece tare da atomatik tsakiya uku jaw Chuck, juya karshen fuska, da m inji da ciki da'irar.Izinin jujjuya ƙarewa shine 0.1-0.2mm.Sauya kayan aiki na ƙarewa don aiwatar da izinin yankewa don saduwa da buƙatun tsangwama da rashin ƙarfi na shinge mai kariya.Cire kayan aikin jujjuya ramin ciki, saka shingen gadi a cikin tsakiyar gaba, matsa shi tare da cibiyar wutsiya bisa ga tsayin da ake buƙata, maye gurbin kayan aikin juyi na silinda don yin taurin kai, sannan gama juyawa don saduwa da buƙatun zane.Bayan wucewa da dubawa, yi amfani da wuka yankan don yanke bisa ga tsawon da ake bukata.Domin yin yankan santsi lokacin da aka katse aikin, za a karkatar da yankan da ƙasa don sanya ƙarshen fuskar aikin ya zama santsi;Ana amfani da ƙaramin yanki na shingen tsaro don yanke ratar kuma a niƙa shi kaɗan.Ana amfani da shingen kariya don rage nakasar kayan aiki, hana girgiza, da yanke abubuwan da ke haifar da fadowa da bumping.

Khadawa

Hanyar sarrafa calo mai sirara da ke sama tana magance matsalar cewa nakasar casing mai bakin bango ko kurakurai masu girma da siffa ba za su iya cika buƙatu ba.Aiki ya tabbatar da cewa wannan hanya tana da babban aikin injina, da kuma aiki mai dacewa, kuma ya dace da yin amfani da sassan bango mai tsawo da bakin ciki.Girman yana da sauƙin ƙwarewa, kuma samar da tsari ya fi dacewa.

Lokacin aikawa: Satumba-29-2022